What is vertical bead mill?

A vertical bead mill is a dispersion machine that uses high-speed rotation of a vertical shaft with discs to agitate and grind materials into fine particles, typically through the impact of small grinding beads like ceramic or glass. It is used to disperse solid particles in a liquid to produce fine powders or suspensions with uniform particle sizes and is commonly employed in industries like paint, inks, and pharmaceuticals for tasks like homogenizing, dispersing, and achieving particle sizes in the sub-micron or nanometer range.

Vertical bead mill working principle

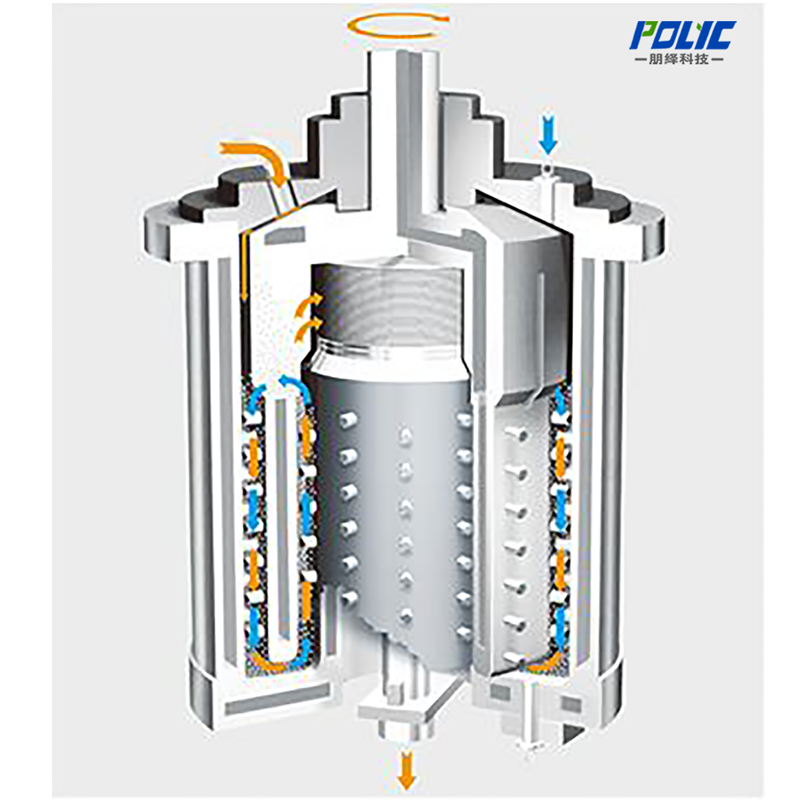

Grinding and dispersion: The vertical bead mill uses ceramic, glass, or metal beads as the grinding media, which are agitated at high speed by a vertical shaft with attached discs.

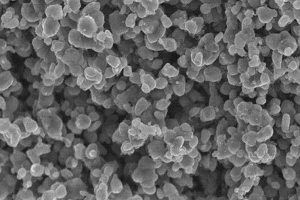

Particle size reduction: The material to be processed is introduced into the grinding chamber. The impact from the beads, the shearing action of the agitated media, and the energy input reduce the size of the solid particles within the liquid.

Gravity and centrifugal force: Gravity pulls the material down, while the rotation of the rotor provides centrifugal force to move it upward, ensuring thorough grinding and a full cycle through the grinding chamber.

Separation: After grinding, centrifugal force is used to separate the product from the grinding media, allowing the finished product to be discharged.

Product Features:

● Product inlet from the top of the PZL Vertical Nano Bead Mill Machine

● Outer plus inner peg milling annulus

● PZL Vertical Nano Bead Mill power input by forced displacement of media in the range 0,2 - 1,5 mm

● Pre-dispersing zone

● Internal media recirculation

● Media separation by centrifuging

● High efficiency cooling of rotor, outer and inner stator + bottom

● Product discharge through removable protection screen on top of inner stator

● Removal of protection screen without draining mill

Product Parameters:

Parameter | Working Volume | Power | Batch | Cooling Water |

Model | L | Kw | L | L/H |

PZL02 | 0.2 | 2.2 | 1 | 500 |

PZL05 | 0.5 | 4 | 2 | 500 |

PZL2 | 2 | 7.5 | 20 | 2000 |

PZL5 | 5 | 18.5 | 50 | 2500 |

PZL10 | 10 | 30 | 100 | 3000 |

PZL20 | 20 | 45 | 200 | 5000 |

PZL30 | 30 | 55 | 500 | 5000 |

Our Advantages:

REAL MANUFACTUREN

24 HOUR ONLINE

CUSTOMIZABLE

30-45 DAYS FAST DELIVERY

STRICTLY QUALITY CONTROL

3 YEARS WARRANTY

Product Details:

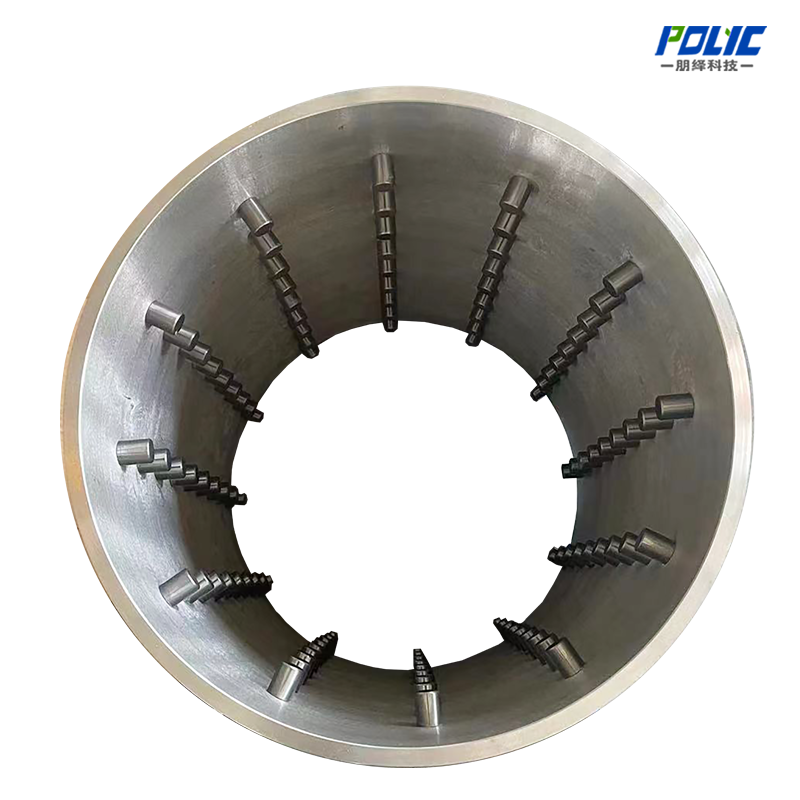

- Grinding pins

- Ingersoll Rand diaphragm pumps

- Inside grinding chamber with pins

- Inside structure

Application:

Paints and Coatings: Achieve vibrant colors and smooth finishes by finely dispersing pigments and fillers. This also results in consistent color and texture.

Pharmaceuticals: Crucial for creating nanoparticles of active pharmaceutical ingredients (APIs) while minimizing contamination.

Cosmetics: Used to homogenize solid components into liquid media for high-quality products.

Agrochemicals: Used for producing finely ground, stable agrochemical suspensions.

Food and Beverages: Used for grinding materials in food production. Vertical three-roll mills are used for grinding chocolate, notes Franli Machine.

Electronic Materials: Used for dispersing particles like titanium oxide and barium titanate for applications such as advanced MLCCs and LC color filters.

Chemical Industry: Essential for producing pigments, dyes, adhesives, and other fine chemicals that require precise particle size control.

- Alumina

- ceramic ink

- coatings

- inkjet ink

- lithium

- nano-material

- nitrile glove

- Pharmaceutics