Bead Mill Working Principle:

A bead mill works by using a rotating agitator to impart high-energy motion to tiny grinding media, or beads, inside a stationary chamber. This agitates a pre-dispersed slurry, causing the beads to collide with the solid particles. The resulting impact and high-intensity shear and friction forces break down the particles into much smaller sizes.

Product Features:

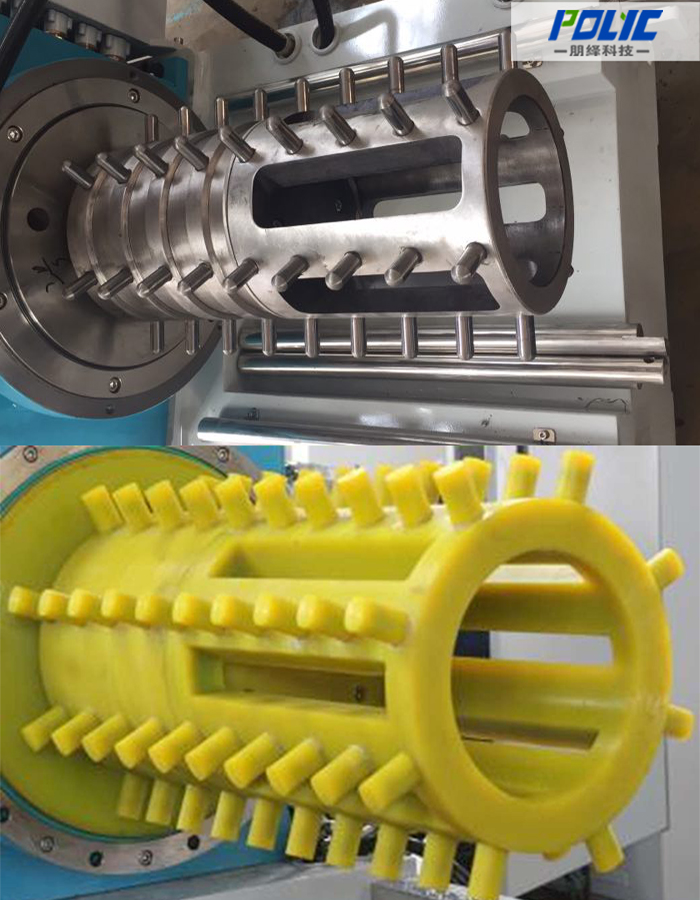

● The PZB pin type bead mill with the new and modular design of rod pin, higher grinding efficiency, more convenient maintenance;

● Uniform distribution of the grinding beads density in the grinding chamber for maximum effectiveness.

● New centrifugal separation system, better separation effect, higher production efficiency;

● Large discharge area, larger flow, more suitable for continuous production and cycle production;

● The mechanical seal of PZB pin type bead mill is designed as a collection-type self-circulation structure, which is more stable and convenient to maintain.

● Forced cooling is carried out on the grinding cylinder, rotor, transmission shaft and discharging end face, and the material temperature is controllable;

Applications of bead mills:

A bead mill is used for various applications such as grinding of food materials, metal oxide for glaze, iron oxide for magnetic tape, dispersing barium titanate for MLCC, and titanium oxide for UV care liquids.

In addition to conventional applications, wet bead millings are being applied to dispersing particles of 20 to 100 nm. Such applications are dispersions of organic pigments for LC color filters, zirconia for hard coatings, and barium titanate for advanced MLCCs. These applications need dispersing conditions with low impact energy. Thus, requirements for wet bead milling that employ micro beads have been increasing.

Another upcoming technology is the grinding of pharmaceutical nanoparticles (APIds). Required is an efficient grinding with less contamination of metal elements, such as zirconium, aluminum, and chromium.

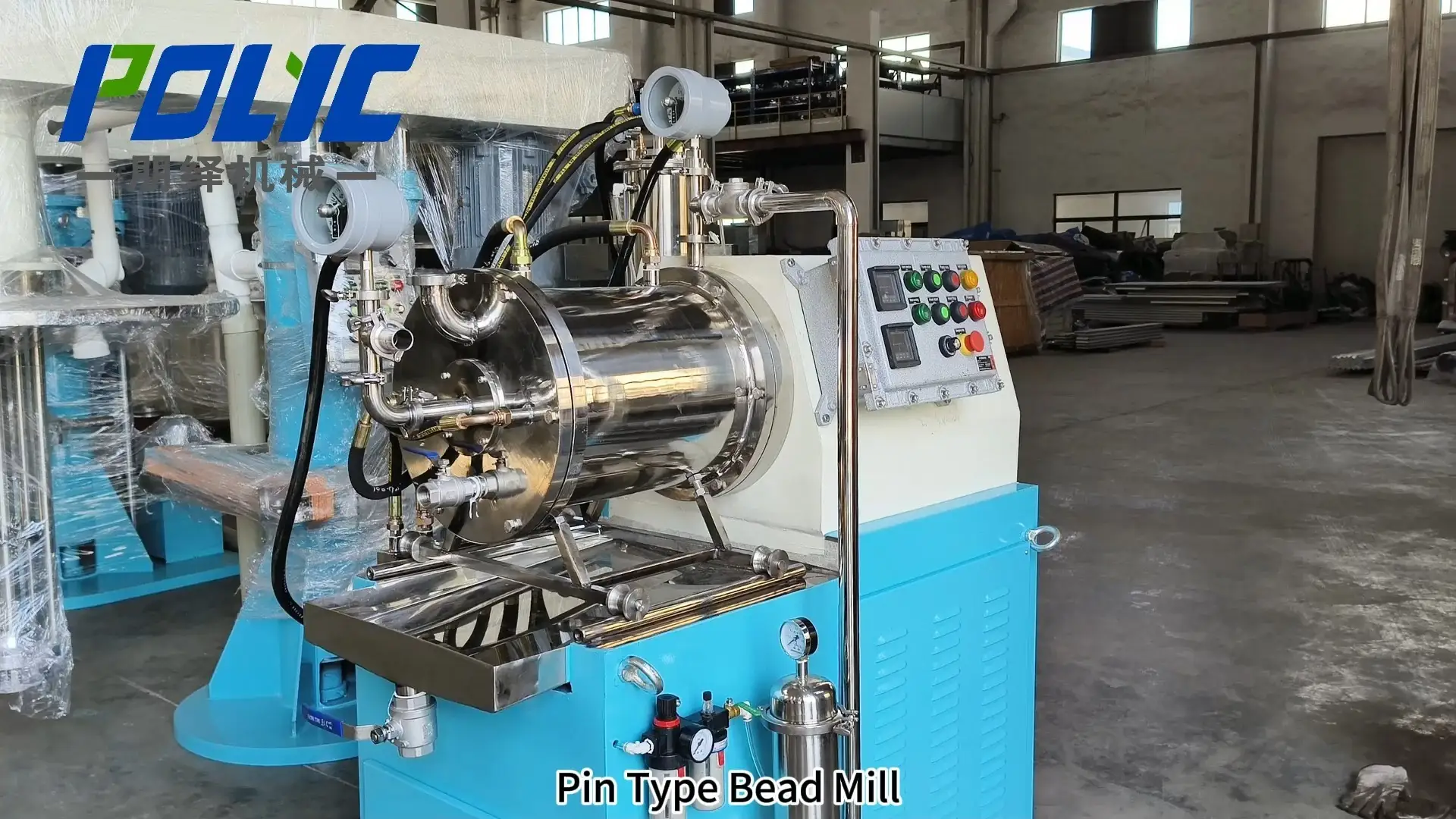

Polyc Pin Type Sand Mill Bead Mill Machine for Pigment Paste. Long service life, efficient grinding, and versatile applications. Video inspection. Welcome to contact us.

Product Parameters:

Parameter of pin type bead mil

Parameter | Working Volume | Power | Batch | Cooling Water |

Model | L | Kw | L | L/H |

PZB6 | 6 | 15 | 300 | 1000 |

PZB10 | 10 | 18.5 | 500 | 1500 |

PZB20 | 20 | 30 | 1000 | 2000 |

PZB30 | 30 | 37/45 | 2000 | 2000 |

PZB60 | 60 | 75 | 3000 | 2500 |

PZB150 | 150 | 160/200 | 5000 | 4000 |

Our Advantages:

REAL MANUFACTUREN

24 HOUR ONLINE

CUSTOMIZABLE

30-45 DAYS FAST DELIVERY

STRICTLY QUALITY CONTROL

3 YEARS WARRANTY

Product Details:

- Grinding Pins

- Opertation Panel

- Temp.& Pressure Meter

- Lubrication Oil Tank

Application:

- Dyes

- Food Additives

- Lithium Battery

- Paint

- Paper Making

- Pesticide

- Pharmaceuticals

- Printing Ink