Product Features:

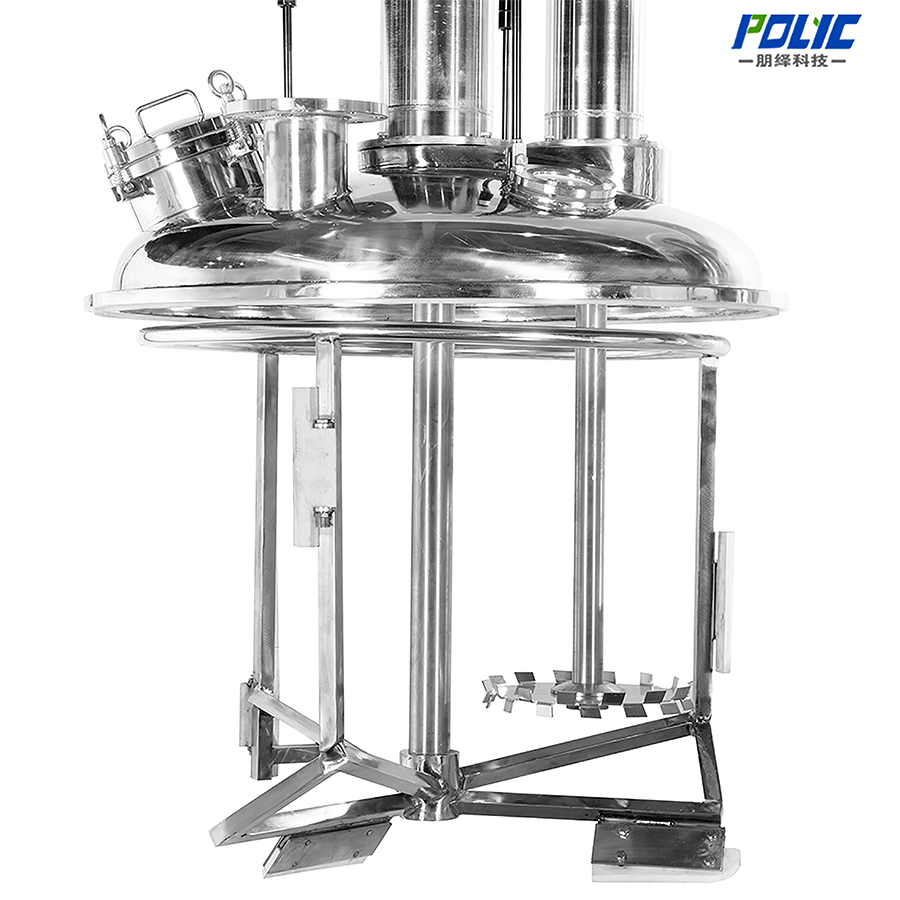

Simple operation by controlling the PM Butterfly Double Shaft Mixer up, stop and down. High stability with big area bedplate, will be buried underground, with bolts for fixing the agitator and the main shaft, easy to disassemble and to clean.

There are Teflon scrapers on the agitator of PM Double Shaft Mixer, it clings to the container and scrapes the materials on the wall off continuously. The PM Double Shaft Mixer container inner wall is precisely lathed and then mirror polished to ensure the scraper can scrape all materials sticking to the wall off without residue, improving the mixing efficiency.

- Designed for dispersing or mixing of different products like paint, ink, putty, adhesive and polymer.

- Typically handles viscosity up to 150,000 cps.

- Ideal for high viscosity product which demands heavy duty and rugged construction.

- Precisely engineered for vibration-free and low noise operation for big batch production.

5.The hydraulic lift and swing mechanism available for usage of single or multiple tanks.

6.Vacuum dispersing or mixing is available on request.

7.Available in fixed speed or frequency inverter driven variable speed.

8.Different clamping mode (belt clamping, manual rotation clamping, pneumatic clamping) are optional for fixing the mixing tank rapidly to prevent any possible accident due to tank displacement...

- Built with tested and proven quality parts and components.

10.ATEX compliance to II 2GD c IIB T3 is available on request.

How does a Dual Shaft Mixer work?

The Dual Shaft Mixer includes an anchor agitator and a high speed disperser. The open disc blade of the disperser, which travels at roughly 5,000 feet per minute, is designed to induce vigorous turbulent flow. It creates a vortex into which dry ingredients can be poured for fast wetting. The anchor feeds product towards the high speed disperser blade and ensures that the mixture is constantly in motion. Teflon scrapers can be installed on the anchor to remove materials from the interior vessel walls, enhancing the mixer's heat transfer capabilities.

What does a Dual Shaft Mixer do?

The Dual Shaft Mixers are a versatile and cost-effective system for making viscous formulations. They provide agitation and high speed dispersive mixing powerful enough to batch viscous solutions, dispersions, suspensions, and emulsions with viscosities in the hundreds of thousands of centipoise.

Product Parameters:

Parameter/Type | PM600 | PM900 | PM1000 | PM1200 |

Tank capacity(L) | 150 | 500 | 600 | 900 |

High speed power(Kw) | 7.5-11 | 18.5-22 | 22-37 | 30-55 |

Low speed power(Kw) | 4-5.5 | 7.5-15 | 11-30 | 11-37 |

High speed blade diameter(mm) | 200 | 250 | 280 | 330 |

Low speed mixing device diameter(mm) | 570 | 860 | 960 | 1160 |

High speed shaft(rpm) | 1500 | 1500 | 1500 | 1500 |

Low speed shaft(rpm) | 90-120 | 60-120 | 120 | 120 |

Max.range of up and down(mm) | 700 | 950 | 1100 | 1100 |

Our Advantages:

REAL MANUFACTUREN

24 HOUR ONLINE

CUSTOMIZABLE

30-45 DAYS FAST DELIVERY

STRICTLY QUALITY CONTROL

3 YEARS WARRANTY

Product Details:

- Buttfly Mixing Shaft

- Electrical Cable Junction Box

- Ex-proof Operation Panel

- Finishied Butterfly Double Shaft Mixer

Application:

- Coating

- Ink

- Paint

- Plasters

- Sealants

- Textured Coating

- Wall Putty

- Waterproof Paint

Project Cases: