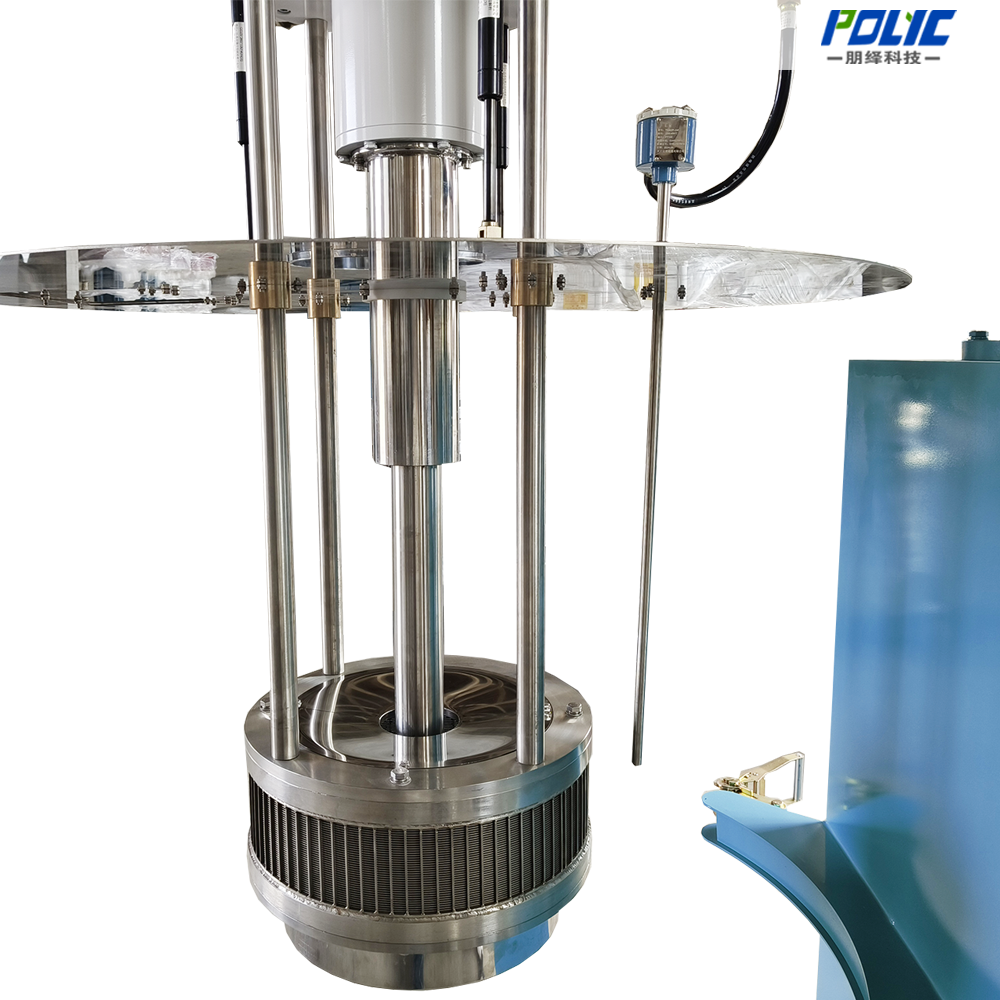

Product Features:

1.Save your cost: Dispersing and grinding are finished in one machine and one container, no need extra pumps, piping, valves etc to .

2. Easy operation: The PZM Basket Mill is easy for cleaning, no residues, convenient product replacement.

3. Little grinding media required. Excellent grinding efficiency and effect.95% purity ceramic beads of high density to obtain size particle homogeneous at the shortest period of time.

4.Can be customized: The basket grinding barrel can be customized with jacket for connection cooling water with cooling function. Equip with temp. sensor and temp. control system if material temp. reach to the max. pre-set data the basket mill will stop automatically

Double-walled container for cooling and heating.

5. Can equip with tank fixed arm with safety device there is an sensor on tank fixed arm if tank not in position the basket mills can't work

6. Labor saving:Modular design of parts make the basket mill machine much more convenient to disassemble, maintain and overhaul, almost no need of professional maintainer.

7. Suitable handle materials Viscosity: ≤ 8000 cps

8. Production Capacity: 50-3000L/day (can OEM according to your requirement)

Benefits for Basket Mill for Ink:

All-in-One Function: Performs pre-mixing, dispersing, and fine grinding in a single operation, simplifying the process.

Submersible Design: The basket is submerged, allowing it to handle various viscosities of liquid ink systems.

High Efficiency: High-speed rotation of the internal basket and grinding media (like beads) creates intense shear and impact for fast particle size reduction.

Particle Size Reduction: Effectively grinds pigments and additives down to micro and nano levels for vibrant, stable inks.

Reduced Solvent Waste: The efficient design leads to less waste and easier cleaning compared to traditional methods, according to Polyc Machine.

Basket mills are versatile wet grinding/dispersing machines used across industries like basket mill for Paints & Coatings, Inks, Pharmaceuticals, Cosmetics, Chemicals, and Food to achieve fine, uniform particle sizes for pigments, additives, active ingredients, etc., by combining high-speed dispersion and grinding in one unit, ideal for small-to-medium batch production, color changes, and achieving high quality, gloss, and stability in final products.

Product Parameters:

Parameter of PZM Basket Mil

Parameter | Power | Speed | Handling capacity | Basket Capacity | Lifting height |

Model | Kw | (rpm) | L | L | mm |

PZM50 | 2.2 | 0-1500 | 10-30 | 1 | 400 |

PZM100 | 4 | 0-1500 | 30-80 | 2 | 500 |

PZM150 | 7.5 | 0-1500 | 80-150 | 4 | 600 |

PZM200 | 11 | 0-1500 | 80-200 | 6 | 700 |

PZM300 | 15 | 0-1500 | 150-300 | 10 | 800 |

PZM400 | 18.5 | 0-1500 | 200-400 | 16 | 900 |

PZM500 | 22 | 0-1200 | 250-500 | 20 | 1000 |

PZM1000 | 30-37 | 0-1200 | 500-1000 | 30 | 1100 |

PSD1500 | 45-55 | 0-1000 | 1000-1500 | 70 | 1300 |

Our Advantages:

REAL MANUFACTUREN

24 HOUR ONLINE

CUSTOMIZABLE

30-45 DAYS FAST DELIVERY

STRICTLY QUALITY CONTROL

3 YEARS WARRANTY

Product Details:

Application:

- Coating

- Ink

- Paint

- Plasters

- Sealants

- Textured Coating

- Wall Putty

- Waterproof Paint

Project Case:

1、This basket mill was sent to Mexico, the customer uses it to grind paint pigments

2、Photo of the basket mill shipped to South Africa, the customer uses it to grind ink

3、The basket mill sent to Saudi Arabia is used by customers to produce various paints