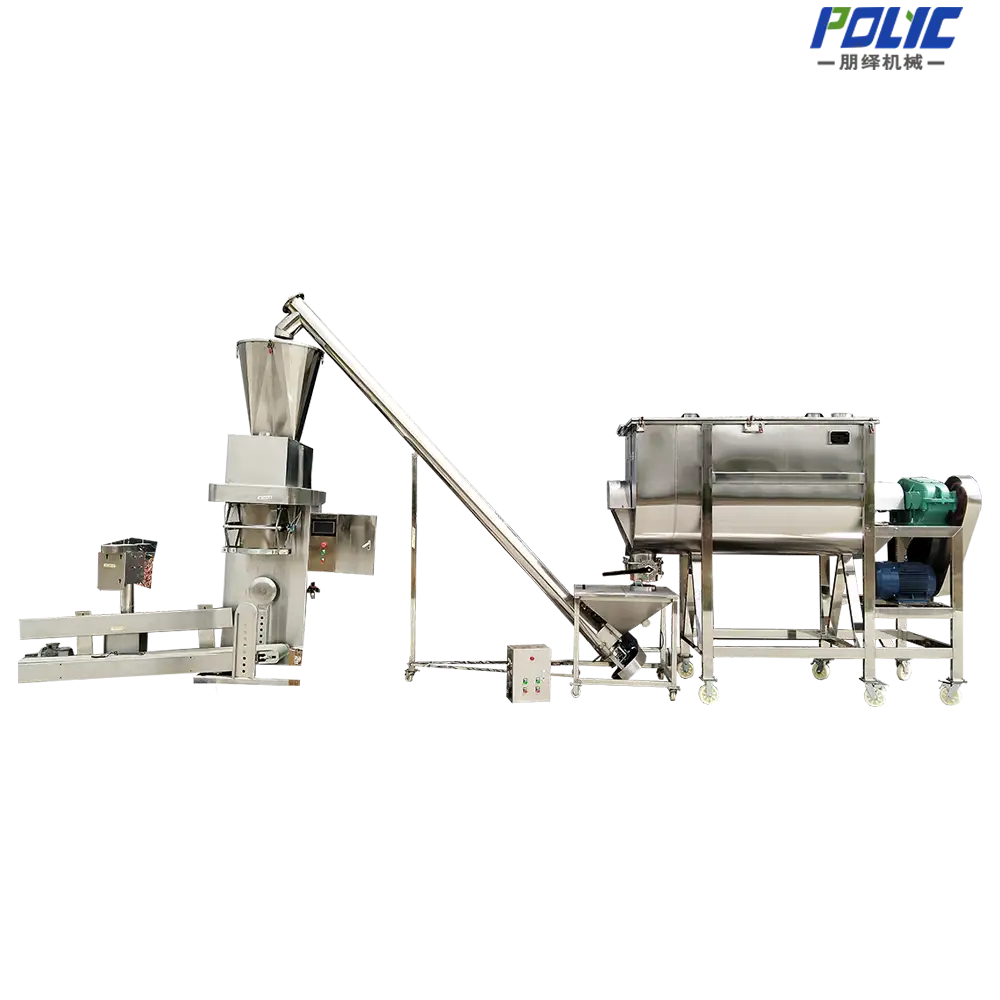

Ribbon Blender Mixer for Lacquer Textured Coating

Ribbon Blender Mixer is a special mixer which is suitable to handle liquid with powder or high viscosity material such as putty, Lacquer, Textured Coating. It can also used for mixing material which is 100% powder no any liquid. POLYC have fixed type Ribbon Blender Mixer and overturning function ribbon mixer which is easy to clear and discharge material

Product Features:

Ribbon Blender Mixer is a newest mixing equipment with high efficiency, high uniformity, high loading coefficient but low energy cost, low pollution and low crush. The special design of double ribbon mixer the materials into high uniformity in a few minutes. On the other hand, ribbon blender mixer shows a wide application from powder mixing, powder-liquid, to paste or materials in high specific gravity (such as putty, really stone paint, metal powder and other materials) and becomes one of the most popular single shaft horizontal mixing equipment.

Working Principle:

Ribbon blender mixer consists of drive disk assembly, double layer ribbon agitator, U-shape cylinder. Inside ribbons move materials toward the ends of the ribbon blender whereas the outside ribbons move material back toward the center of the ribbon blender, therefore, materials get fulling mixing. Materials flow direction are determined by ribbon angle, direction, twining method. Material outlet are located in the middle of cylinder bottom. Outside ribbon driven by main shaft moves materials to discharging to ensure no discharging dead zone.

Technical Parameters:

| Type | PRM | ||||||||||

| Spec(m³) | 0.5 | 1 | 2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 |

| Working capacity | 0.4-0.6 | ||||||||||

| Power | 5.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 55 | 75 |

| Speed(rpm) | 66 | 41 | 41 | 33 | 33 | 26 | 26 | 26 | 20 | 20 | 17 |

| Dimension L W H | 1672 | 1970 | 2480 | 2880 | 3026 | 3518 | 3905 | 4398 | 4500 | 4486 | 5363 |

| 1142 | 1437 | 1561 | 1895 | 1947 | 1945 | 1683 | 1960 | 2070 | 2250 | 2250 | |

| 1300 | 1500 | 1830 | 2083 | 2235 | 2233 | 2286 | 3150 | 2667 | 2737 | 3070 | |

| Weight(Kg) | 955 | 1400 | 2500 | 3300 | 3600 | 4620 | 5300 | 6800 | 8902 | 9520 | 9950 |

Our Advantages:

Product Details:

Application: