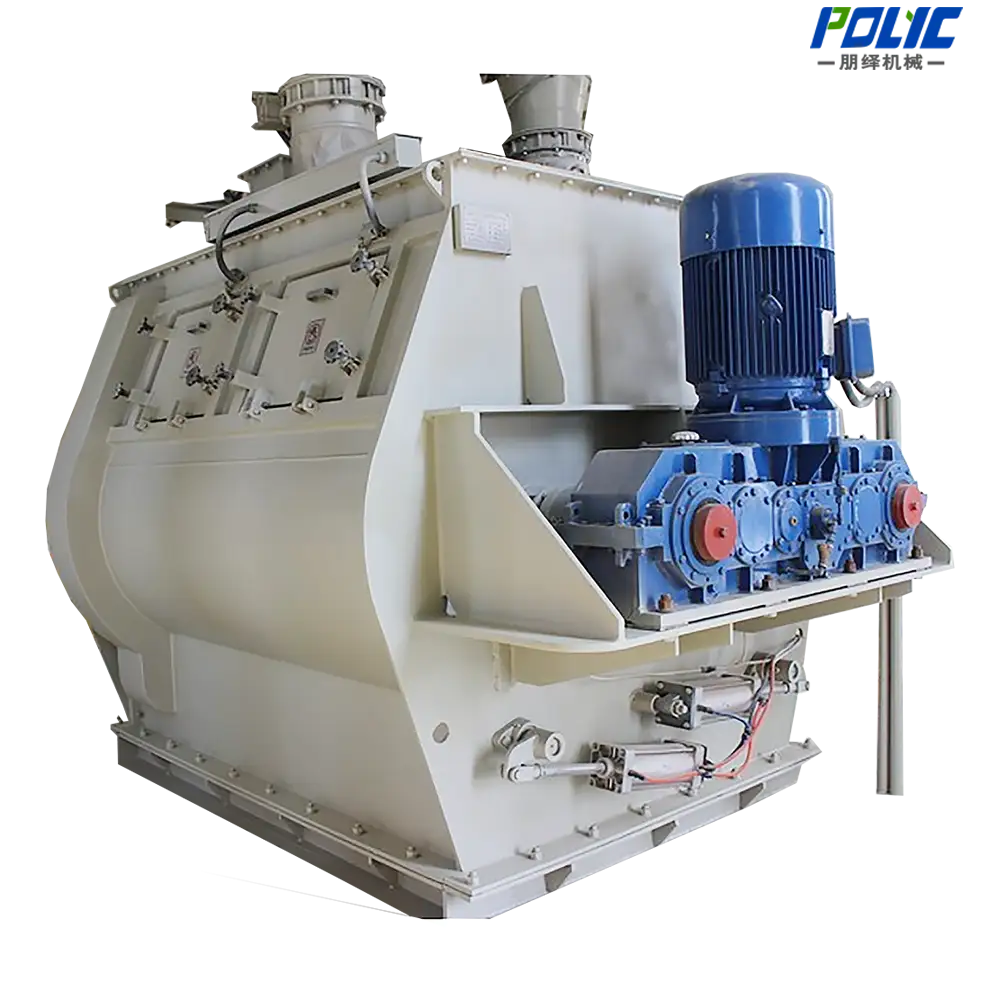

Horizontal non-gravity Mixer for Mortar

Horizontal non-gravity mixer full use of the principle of convection mixing. Inside the chamber, there are two sets of blades rotating in opposite directions. Each blade has been scientifically calculated to obtain reasonable spacing and angle values. with high efficiency, high uniformity, high loading coefficient but low energy cost, low pollution and low crush. Agitators, designed in special angle, rotates in same but opposite direction and shows a nice mixing, smashing, dispersing results. It is widely used in powder-powder, powder-liquid, powder-particles mixing. It is also able to used for materials in different specific gravity and particles in a wide range of sizes

Application Industry:

Suitable for the mixing of pharmacy, food, pesticide, dye, chemical industry, plastic, lithium battery, ceramic, chemical fertilizer, rubber, mortar and etc.

Applicable Materials:

Powders with fluidity whose specific gravity is up to 3g/cm³, such as milk powder, food activities, organic chemical fertilizer, dry powder mortar, specific building materials, antiflame materials and etc.

Advantages of the Horizontal non-gravity mixer:

1. Manual, electric and pneumatic options with various discharge types are available.

2. The high-speed rotating cutter installed has the function of rapidly dispersing fibers.

3. The meteorological balance device makes the mixing more uniform.

4. The combined blade structure significantly reduces maintenance costs.

5. The large-opening discharge reduces the dead zones in the mixer and makes the discharging cleaner and faster.

6. It can be used for solid-solid (powder and powder) mixing, solid-liquid (powder and liquid) mixing and drying operations.

7. The mixing speed is fast, and the general powder mixing only takes about 2-3 minutes.

8. It can be operated in a sealed manner, with reliable operation and convenient maintenance.

Working Principle:

The Horizontal non-gravity mixer makes full use of the principle of convection mixing. Inside the chamber, there are two sets of blades rotating in opposite directions. Each blade has been scientifically calculated to obtain reasonable spacing and angle values. The rotation of the blades throws the materials into the spatial flow layer, causing a momentary loss of gravity. They fall into each other's areas, and an agitated loss zone and rotating vortex form in the middle layer. A flow layer is formed at the bottom of the mixer, and the materials exhibit three-dimensional compound motion, thereby achieving a comprehensive and rapid uniform mixing effect. This equipment is suitable for drying and mixing of chemicals, metallurgy, construction, coatings, resins, pesticides, feed, and powder materials.

Technical Parameters:

| Model | Full Volume m³ | Loading coefficient | Power kw | Speed r/min |

| PYZL-1.0 | 1.0 | ≤0.6 | 11 | 43 |

| PYZL-2.0 | 2.0 | ≤0.6 | 18.5 | 43 |

| PYZL-3.0 | 3.0 | ≤0.6 | 22 | 38 |

| PYZ-4.0 | 4.0 | ≤0.6 | 30 | 38 |

| PYZ-6.0 | 6.0 | ≤0.6 | 45 | 34 |

| PYZ-8.0 | 8.0 | ≤0.6 | 55 | 29 |

| PYZ-10.0 | 10.0 | ≤0.6 | 75 | 29 |

| PYZ-12.0 | 12.0 | ≤0.6 | 90 | 29 |

| PYZ-15.0 | 15.0 | ≤0.6 | 110 | 26 |

√ The above listed Max. processing capacity is calculated as per powder with specific gravity 1 as medium. The model selection should depend on the comprehensive factors such as materials viscosity, specific gravity etc.

√ We can’t list all volumes, can also customize according to customer’s special requirement, you can contact us with more details then we work on suitable solution for you

Our Advantages:

Product Details:

Application: