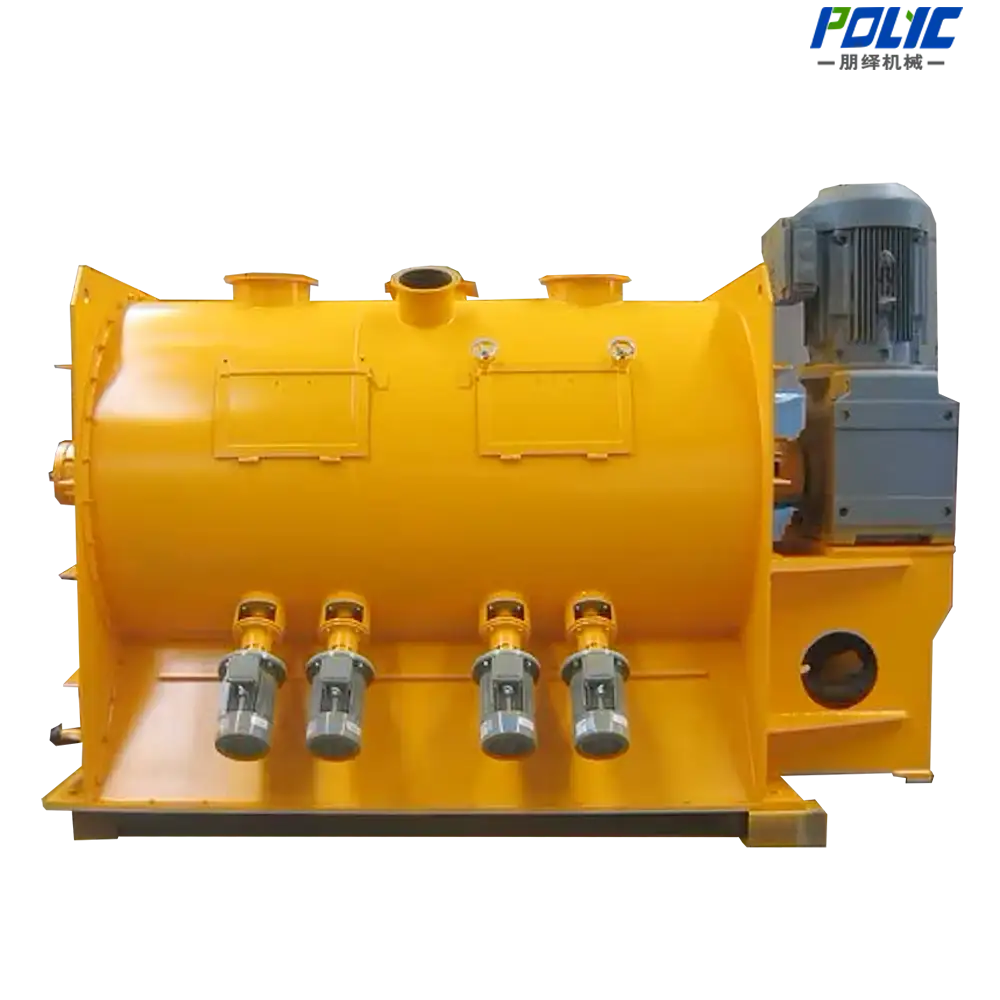

Horizontal Plough Mixer for Powder and Particles

Horizontal plough mixer is a Germany-technical late-model mixing equipment with high efficiency, high uniformity, high loading coefficient but low energy cost, low pollution and low crush. The agitator consists of multi-group of plough and fly-cutter which works together to mixing, smash, and dispersing materials. It is widely used in the mixing of powder-powder, powder-liquid and powder-particles, especially for the materials which may get aggregation during mixing. Liquid can be sprayed into powders. Vacuum system and drying system are also in option.

Application Industry:

Suitable for the mixing of pharmacy, food, pesticide, dye, chemical industry, plastic, lithium battery, ceramic, chemical fertilizer, rubber, mortar and etc.

Applicable Materials:

Powders with fluidity whose specific gravity is up to 5g/cm³, liquid content is up to 20%, such as medical intermediate, flavoring, pesticide, reactive dyes, water-free dirt, lithium cobalt oxides battery material and etc.

It is widely used in construction material, chemicals, medicine, agricultural medicine,food, feed and feed additives, dyes, paints, plastics and other industries, such as solid - solid (powder and powder), mixed solid-liquid and wet granulation, drying and composite technology. It is especially suitable for the mixture of viscous or rubbery additives.

Advantages of Horizontal plough mixer:

1. Short mixing time, can mix the materials that are big difference in granularity and density

2. work under sealed condition, run stably, dust concentration is low, no pollution to the environment.

3. Can add spraying device, can separate and mix the lump materials.

4. It has the best performance of separating the fibers.

5. Products are designed according to the characteristic of raw and finial products materials and manufacturing process (i.e. Pressure requirement, proportion of solid and liquid) to meet the requirements in driving device, operability, leak proofness and etc. areas. special fly-cutter also be improved for environmental engineering sludge treatment.

Working Principle:

The Horizontal plough mixer consists of transmission mechanism, horizontal drum, colter and fly cutter. The material flow forwards in axial direction along the drum shell by the force from the colter. The materials will be thrown to all directions by high speed rotating fly cutter when pass by it to smash the agglomeration achieve uniform mixing in the shorter time.

Technical Parameters:

| Model | Full Volume m³ | Loading coefficient | Main motor power (kw) | Flying blade motor power (kw) & qty | Speed r/min |

| PYPM-0.5 | 0.5 | 0.4-0.6 | 7.5 | 3x2 | 85 |

| PYPM-1.0 | 1.0 | 0.4-0.6 | 11 | 3x2 | 85 |

| PYPM-2.0 | 2.0 | 0.4-0.6 | 22 | 4x3 | 68 |

| PYPM-4.0 | 4.0 | 0.4-0.6 | 37 | 4x4 | 57 |

| PYPM-6.0 | 6.0 | 0.4-0.6 | 55 | 4x4 | 57 |

| PYPM-8.0 | 8.0 | 0.4-0.6 | 75 | 4x4 | 42 |

| PYPM-10.0 | 10.0 | 0.4-0.6 | 90 | 5.5x5 | 42 |

√ The above listed Max. processing capacity is calculated as per powder with specific gravity 1 as medium. The model selection should depend on the comprehensive factors such as materials viscosity, specific gravity etc.

√ We can’t list all volumes, can also customize according to customer’s special requirement, you can contact us with more details then we work on suitable solution for you

Our Advantages:

Product Details:

Application: