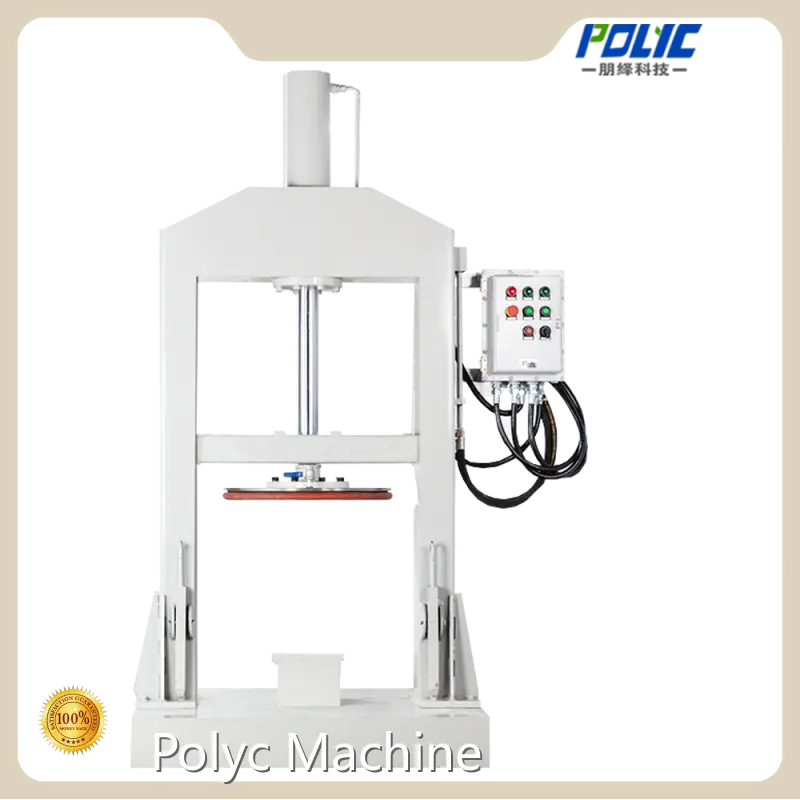

Chemical Machine by Polyc Machine

Product details of the chemical machine

Product Overview

To ensure the quality of Polyc Machine chemical machine, the first-rate materials are used in the production, which acts as an important role in guaranteeing the basic quality assurance. In order to conform to the fashion of chemical machine industry, our products are developed consistuted by the leading technology. Polyc Machine has professional team to help to strictly test the quality of chemical machine.

Product Description

Compared with other products in the same category, chemical machine has the following competitive advantages.

Product Features:

- The hydraulic discharging machine must match the mixing vessel. The seal ring of the cover much match the mixing vessel well to push the materials inside the mixing vessel out under the action of the oil cylinder.

- The hydraulic discharging machine takes the hydraulic oil as a driving source. It is a piece of equipment with big motion energy, easy operation, compact design and easy to clean.

- The hydraulic discharging machine is suitable for discharging materials with viscosity from low to high. The viscosity range can be around 10,000cp-1,000,000cp. It can greatly improve filling progress for the high viscosity products.

- 4. It is widely used for high viscosity of the material after mixing such as putty, glue, adhesive, silicone sealant, Silicone structural adhesive, black glue, weather-resistant adhesive, etc. high viscosity materials.

Product Parameters:

Parameter of PHD Hydraulic Discharging Machine

|

Parameter/Type |

Motor Power |

Tank Diameter |

Disc Diameter |

Max. lift |

|

PHD900 |

4 |

900 |

900 |

1150 |

|

PDH1000 |

4 |

1000 |

1000 |

1150 |

|

PDH1100 |

5.5 |

1100 |

1100 |

1250 |

|

PFDH1200 |

5.5 |

1200 |

1100 |

1250 |

Our Advantages:

REAL MANUFACTUREN

24 HOUR ONLINE

CUSTOMIZABLE

30-45 DAYS FAST DELIVERY

STRICTLY QUALITY CONTROL

3 YEARS WARRANTY

Product Details :

-

Completed Discharging Machine

-

Control Panel

-

Extruder with mixer

-

Pressing plate with O ring

Application :

-

Addhesive

-

Car Glue

-

Lithium Paste

-

New composite material

-

Pharmaceuticals industries

-

Plasters

-

Sealant

-

Wall Putty

Project Cases:

Company Advantages

Located in shang hai, Shanghai Polyc Technology Co.,Ltd is a comprehensive enterprise. We are dedicated to the production, processing, and sales of Bead Mill,Basket Mill,Disperser,Inline Disperser,Industrial Mixer,High Shear Emulsifier,Mixing Kettles,Mixing Kettle & Reactor,Production Line. With the business philosophy of 'integrity first, quality assurance, innovation seeking', our company wholeheartedly explores new fields, develops new products, and provides good services. We strive to make contribution to the industry development. Our grassroots employees, middle-level cadres, professional and technical personnel, and elite leaders form a pyramid-like team to drive our moving forward with strong strength. Since the establishment, Polyc Machine has always been focusing on the R&D and production of Bead Mill,Basket Mill,Disperser,Inline Disperser,Industrial Mixer,High Shear Emulsifier,Mixing Kettles,Mixing Kettle & Reactor,Production Line. With great production capability, we can provide customers with personalized solutions according to their needs.

With rich experience and exquisite technology, we are looking forward to building good cooperation with partners from all walks of life and creating a better tomorrow!