Polyc Machine Horizontal Ribbon Mixer Supply

Product details of the horizontal ribbon mixer

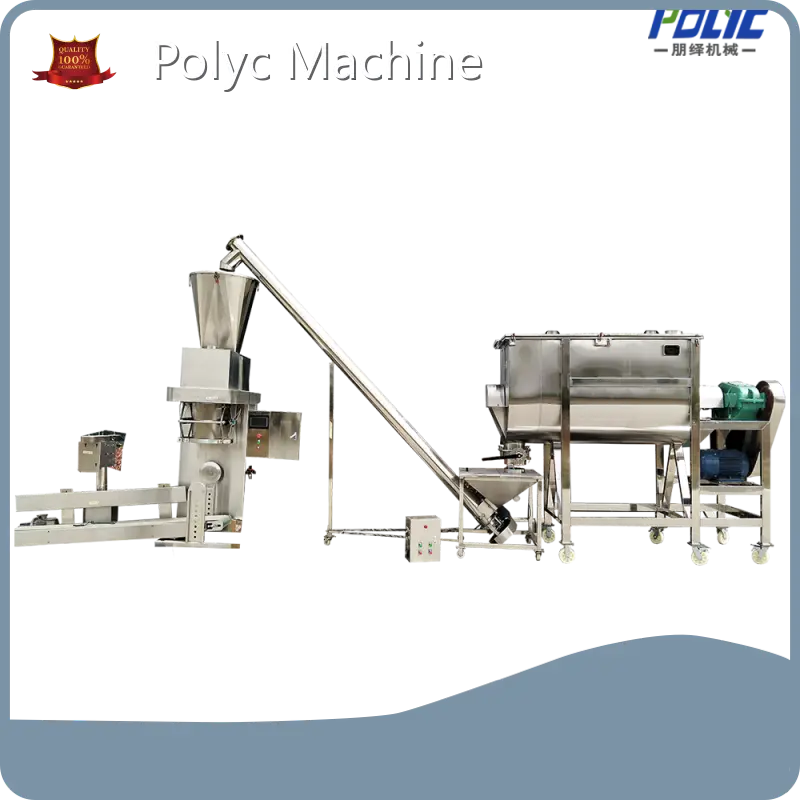

Product Overview

Each detail of Polyc Machine horizontal ribbon mixer is carefully crafted by using the latest advanced technology. Strict quality control system is the guarantee of product quality. Polyc Machine's horizontal ribbon mixer can play a role in various industries. It is formidable that unqualified horizontal ribbon mixer are sold to clients in Polyc Machine.

Product Information

horizontal ribbon mixer has the following differentiated advantages compared with other products in the same category.

Product Features:

Ribbon Blender Mixer is a newest mixing equipment with high efficiency, high uniformity, high loading coefficient but low energy cost, low pollution and low crush. The special design of double ribbon mixer the materials into high uniformity in a few minutes. On the other hand, ribbon blender mixer shows a wide application from powder mixing, powder-liquid, to paste or materials in high specific gravity (such as putty, really stone paint, metal powder and other materials) and becomes one of the most popular single shaft horizontal mixing equipment.

Working Principle:

Ribbon blender mixer consists of drive disk assembly, double layer ribbon agitator, U-shape cylinder. Inside ribbons move materials toward the ends of the ribbon blender whereas the outside ribbons move material back toward the center of the ribbon blender, therefore, materials get fulling mixing. Materials flow direction are determined by ribbon angle, direction, twining method. Material outlet are located in the middle of cylinder bottom. Outside ribbon driven by main shaft moves materials to discharging to ensure no discharging dead zone.

Technical Parameters:

| Type | PRM | ||||||||||

| Spec(m³) | 0.5 | 1 | 2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 |

| Working capacity | 0.4-0.6 | ||||||||||

| Power | 5.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 55 | 75 |

| Speed(rpm) | 66 | 41 | 41 | 33 | 33 | 26 | 26 | 26 | 20 | 20 | 17 |

| Dimension L W H | 1672 | 1970 | 2480 | 2880 | 3026 | 3518 | 3905 | 4398 | 4500 | 4486 | 5363 |

| 1142 | 1437 | 1561 | 1895 | 1947 | 1945 | 1683 | 1960 | 2070 | 2250 | 2250 | |

| 1300 | 1500 | 1830 | 2083 | 2235 | 2233 | 2286 | 3150 | 2667 | 2737 | 3070 | |

| Weight(Kg) | 955 | 1400 | 2500 | 3300 | 3600 | 4620 | 5300 | 6800 | 8902 | 9520 | 9950 |

Our Advantages:

Product Details:

Application:

Company Information

Located in shang hai, Shanghai Polyc Technology Co.,Ltd, a company, specializes in the business of Bead Mill,Basket Mill,Disperser,Inline Disperser,Industrial Mixer,High Shear Emulsifier,Mixing Kettles,Mixing Kettle & Reactor,Production Line. Polyc Machine regards 'pragmatism, dedication, innovation' as our spirit and runs the business based on the philosophy of 'sincerity-based cooperation and mutual benefit'. We are committed to providing new and old customers with better products and more professional services. Our company has widely recruited talents to form a high-level talent team. Our team members are highly-educated and excellent. Based on the actual needs of our customers, we provide a one-stop solution for them with the purpose of rational allocation of Bead Mill,Basket Mill,Disperser,Inline Disperser,Industrial Mixer,High Shear Emulsifier,Mixing Kettles,Mixing Kettle & Reactor,Production Line.

If you are interested, please contact customer service staff for consultation!